INNOVATION

Our I+D+i department is continuously in search of the best solutions for the needs detected by our Continuous Improvement system, transmitted by or customers, or detected through monitoring technology evaluation tools, which have allowed us to incorporate 4.0 technology in our equipment and have enabled the creation of new patents in developments.

Innovative and Sustainable 4.0 Solutions

Rotary, with over 40 years of experience in innovative solutions for sectors such as the envelope, hygienic products, and batteries, has evolved to innovative and sustainable 4.0 solutions. This process has been possible thanks to the concerns brought to us by our customers in their search for efficiency in their processes and a reduction of operation costs.

Our technical team has managed to develop innovative solutions, incorporating Tungsten Carbide, in the manufacturing of envelopes, hygienic products, and batteries, achieving an improvement in the quality of the final products, increasing productivity, using SMED-type systems, monitoring data to identify points of improvement, or applying adaptive solutions to the process.

Innovation Areas

Product Engineering

Technical product innovations are focused on providing solutions using operation cost and sustainability criteria. The I+D+i department is working on solutions focused on increasing:

- Efficiency: lower maintenance and greater durability of components incorporating Tungsten Carbide.

- Effectiveness: higher quality of the final product.

- Performance: increase in cutting speed.

- Sustainability: To manage to integrate our solutions into a circular economy, reduce the energy used, and reduce residue generated during the final product manufacturing process.

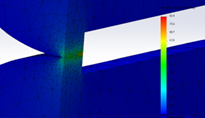

- For this, it counts on the collaboration of local advanced manufacturing Technological Centers and our customers’ technical departments, in addition to FEM calculation tools and surface design specific software.

Process Engineering

Technical process innovations have been developed to increase the efficiency of our production processes, and improve the quality of the products obtained, especially related to precision and finishings obtained, as well as improving the performance of the machines.

In the last few years, we have incorporated cutting-edge CAD/CAM technologies, developed post-processors with proprietary technology and know-how, specific process simulators that guarantee ultra-precision finishing, in Tungsten Carbide, of our components, enabling homogeneity in the mechanisation processes. Controlling all Hard Metal processes with 4.0 technology in order to assess the efficiency of productive processes. All this has been incorporated with the help of local advanced manufacturing Technological Centers, where they have collaborated in the development of tooling strategies and machining processes with our own know-how.

CONTACT

Would you like more information?

We will reply as soon as possible.